OCL-210X 水平式單給袋包裝機(jī) Horizontal single-to-bag packaging machine

全國(guó)服務(wù)熱線:

159-1595-6886(微信同號(hào))全國(guó)服務(wù)熱線:

159-1595-6886(微信同號(hào))主要特點(diǎn):Main feature

1、計(jì)量包裝系統(tǒng)有水平式給袋包裝機(jī)與下料系統(tǒng)組成;

1. The metering and packaging system consists of a horizontal bag-feeding packaging machine and a blanking system;

2、放袋槽放袋方便簡(jiǎn)單,配備自動(dòng)壓袋裝置;

2. The bag-putting slot is convenient and simple for bag-putting, equipped with automatic bag-pressing device;

3、配置進(jìn)口壓力感應(yīng)裝置,達(dá)到不下料不封的效果,節(jié)約包裝袋;

3. Equipped with imported pressure sensing device to achieve the effect of no blanking and no sealing, saving packaging bags;

4、采用彩色觸摸式顯示屏,簡(jiǎn)單操作,多功能設(shè)計(jì);

4. Adopting color touch screen, simple operation and multifunctional design;

5、機(jī)器采用不銹304外觀,碳鋼機(jī)架部分與部分配件做耐酸、耐鹽防腐處置層加工。

5. The machine adopts stainless 304 appearance, and the carbon steel frame part and some accessories are processed with acid-resistant, salt-resistant and anticorrosive treatment layer.

6、選材要求:大部分配件以模具化生產(chǎn)成型,主要材料選用304不銹與氧化鋁。

6. Material selection requirements: Most of the accessories are formed by mold production, and the main materials are 304 stainless steel and alumina.

7、可選配各種打碼、噴碼、排氣、沖孔系統(tǒng);

7. Various coding, coding, exhaust, and punching systems are optional;

適用范圍:Scope of application

本機(jī)包裝類型:Native packaging type

01.固體類:糖果、花生、青豆、開(kāi)心果、膨化食品等固體類物料的包裝。

01. Solids: packaging of solid materials such as candies, peanuts, green beans, pistachios, puffed foods, etc.

02.顆粒類:豆類、結(jié)晶味精、結(jié)晶鹽、顆粒狀藥品、膠囊、種子、化學(xué)調(diào)料、雞精、瓜子、農(nóng)藥、肥料、飼料等顆粒類物料的包裝。

02. Granules: beans, crystalline monosodium glutamate, crystalline salt, granular medicines, capsules, seeds, chemical seasonings, chicken essence, melon seeds, pesticides, fertilizers, feed and other granular materials.

03.粉劑類:調(diào)味品、奶粉、素食粉、五谷粉、葡萄糖、生粉、面粉等粉劑物料的包裝。

03. Powders: packaging of condiments, milk powder, vegetarian powder, grain powder, glucose, corn powder, flour and other powder materials.

04.液體類:醬油、米醋、果汁、飲料等液體類物料的包裝。

04. Liquids: packaging of liquid materials such as soy sauce, rice vinegar, fruit juice, and beverages.

05.醬體類:番茄醬、辣椒醬、豆瓣醬等醬體類物料的包裝。

05. Sauce body: packaging of ketchup, chili sauce, bean paste and other sauce body materials.

本機(jī)技術(shù)參數(shù):Technical parameters of this machine

| 包裝速度 Packaging speed | 10-45bags/min(視產(chǎn)品重量而定Depends on product weight) |

| 總功率 Total power | 22.5KW(主機(jī))host) |

| 包裝尺寸 Package Size | 100-210mm/110-320mm(W*L) |

| 供電電源 Power supply | 380V |

| 整機(jī)重量 Total Weight | 900KG |

| 包裝容量 Packing capacity | 300g-2kg(視物料而定Depends on the material) |

| 耗氣量 Air consumption | 0.7m3/min |

| 包裝袋類型 Bag type | 自立袋、四邊封袋、拉鏈袋、手提袋、紙袋等各種預(yù)制袋 |

| Various prefabricated bags such as self-supporting bags, four-side sealing bags, zipper bags, handbags, paper bags, etc. |

本機(jī)主要配置:Main configuration of this machine

| 01.氣動(dòng)元件:Pneumatic components | |

| 給袋汽缸:To bag cylinder | 臺(tái)灣亞德客AirTAC Taiwan |

| 其他汽缸:Other cylinders | 臺(tái)灣亞德客AirTAC Taiwan |

| 氣動(dòng)電磁閥:Pneumatic solenoid valve | 臺(tái)灣亞德客AirTAC Taiwan |

| 真空壓力表:Vacuum pressure gauge | 臺(tái)灣亞德客AirTAC Taiwan |

| 氣管、接頭、三聯(lián)體:Trachea, joint, triplet | 臺(tái)灣亞德客AirTAC Taiwan |

| 02.電氣元件:Electrical components | |

| 顯示屏(觸摸屏):Display (touch screen) | 臺(tái)灣威倫Weilun |

| 編碼器:Encoder | 日本歐姆龍Omron |

| 變頻器:Frequency converter | 深圳金鐘Shenzhen Admiralty |

| 控制開(kāi)關(guān)、按鈕、繼電器:Control switches, buttons, relays | 法國(guó)施耐德Schneider |

| 光電檢測(cè)元件:Photoelectric detection element | 奧托尼克斯Autonics |

| PLC: | 億維Edimensional |

| 中間繼電器:Intermediate relay | 美國(guó)ABBAmerican ABB |

特點(diǎn):1、放袋結(jié)構(gòu) 2、送袋裝置 3、自動(dòng)上袋裝置、 4、機(jī)械手夾袋 5、真空開(kāi)袋 6、充填物料 7、整形 8、封口 9、成品輸送。

Features: 1. Bag placing structure 2. Bag feeding device 3. Automatic bag loading device 4. Manipulator gripping bag 5. Vacuum bag opening 6. Filling material 7. Shaping 8. Sealing 9. Finished product conveying.

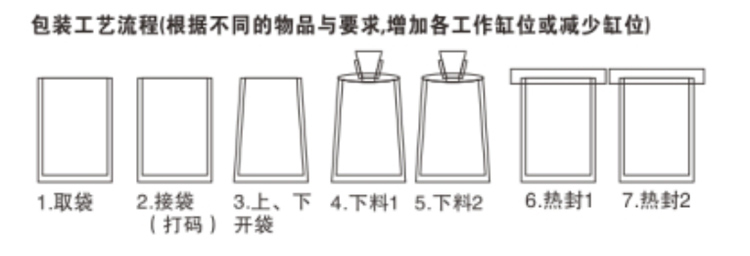

HDS-210包裝機(jī)工藝流程:Packaging machine process

配套粉劑螺桿下料系統(tǒng)示圖:Diagram of supporting powder screw feeding system

配套液體下料系統(tǒng)示圖:Diagram of supporting liquid feeding system

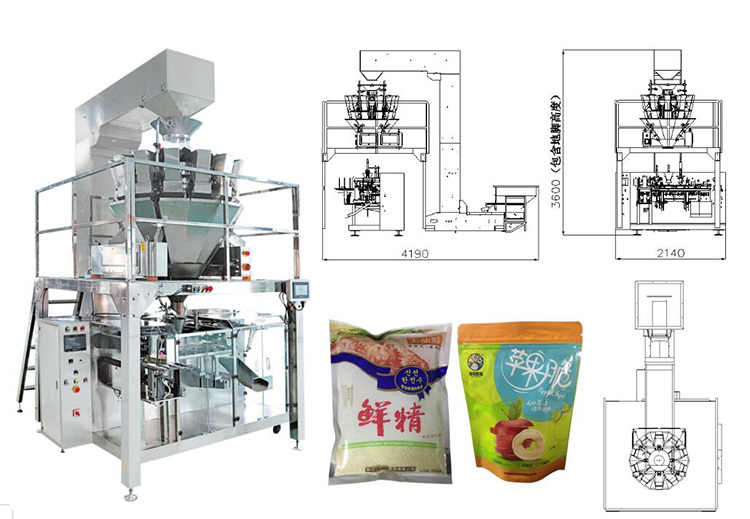

配套電子稱顆粒下料系統(tǒng)示圖:Diagram of supporting electronic scale particle blanking system